It’s interesting. Not everyone wants the biggest, baddest and greatest. I for one, have always loved building stuff. Always looking to whats next. Wondering whats the next cool thing that no one has done before. I have wanted to be on the forefront, which eventually took me down the path of doing my best in perfecting the solid axle swap on the earlier Nissans. We did some amazing builds, but in the end, there wasn’t a big following for that level of 4×4 in the Nissan world. Most of you aren’t aiming for the biggest rocks, trying to set records or get on the cover of magazines. It’s been shown that you just want a solid rig that performs well enough to hit some challenging trails, go camping and explore cool places. Which is awesome. I enjoy those things too. So when the solid axle swap endeavours ended, I started looking into offering a titan swap kit that was a bit different than anything else on the market.

It’s interesting. Not everyone wants the biggest, baddest and greatest. I for one, have always loved building stuff. Always looking to whats next. Wondering whats the next cool thing that no one has done before. I have wanted to be on the forefront, which eventually took me down the path of doing my best in perfecting the solid axle swap on the earlier Nissans. We did some amazing builds, but in the end, there wasn’t a big following for that level of 4×4 in the Nissan world. Most of you aren’t aiming for the biggest rocks, trying to set records or get on the cover of magazines. It’s been shown that you just want a solid rig that performs well enough to hit some challenging trails, go camping and explore cool places. Which is awesome. I enjoy those things too. So when the solid axle swap endeavours ended, I started looking into offering a titan swap kit that was a bit different than anything else on the market.

The more I looked at different setups and listend to feedback, the more I realized there was a better way to be doing titan swaps that would address multiple issues.

For one, many of the titan swap kits used uniballs in place of upper balljoints, and heims joints in place of bushings. This allows for more travel but at the expense of long lasting low maintentance parts. In dry climates, these parts are great, However, in harsh winter environments, the uniballs and heims wear out much faster than a greasable balljoints and bushings. The salt and other checmials used for managing icy raods, heavily accelerate the decline of these parts leading to the need of replacement about once a year. This means, taking your suspension apart, replacing costly parts and getting an alignment every time. The alternative option of using ballsjoints and bushings ,were lacking the suspension travel of the uniball options. These problems had my attention.

Another place for improvement is that many people strived to run 4″ of lift on a titan swap suspenion which really pushed the limits of the titan width IFS suspension system. The stance looks great but trail performance is lacking as there isn’t hardly any downtravel left to have a properly functioning suspension system. I’ve seen way too many xterras climb obstacles in Moab, UT, and even to this day on Instagram, where an obstacle is appraoched and as one front wheel starts to climb. The spring doesn’t compress and the opposite side is lacking any downtravel which robs any ability to keep the wheel on the ground. 3-wheel action… everywhere. Attempting to put longer coilovers in would result in the common coilbucket contact issues. One solution would be to run about 2.5″ – 3″ of lift. The performance would be drastically improved… but we haven’t talked about tires yet. It’s been proven that there are a lot of xterra and frontier owners wanting to go to 35″ tires, which simply don’t fit in the wheelwells / fenders. There are 2 options, start trimming, or get a body lift. In the interest of staying away from body lifts, most people start trimming. One could carfully trim the fenders following the factory curve nearest the firewall but the 35″ tires would smash into the fender at full compression unless you cut upwards too… which in my opinion looks stupid.

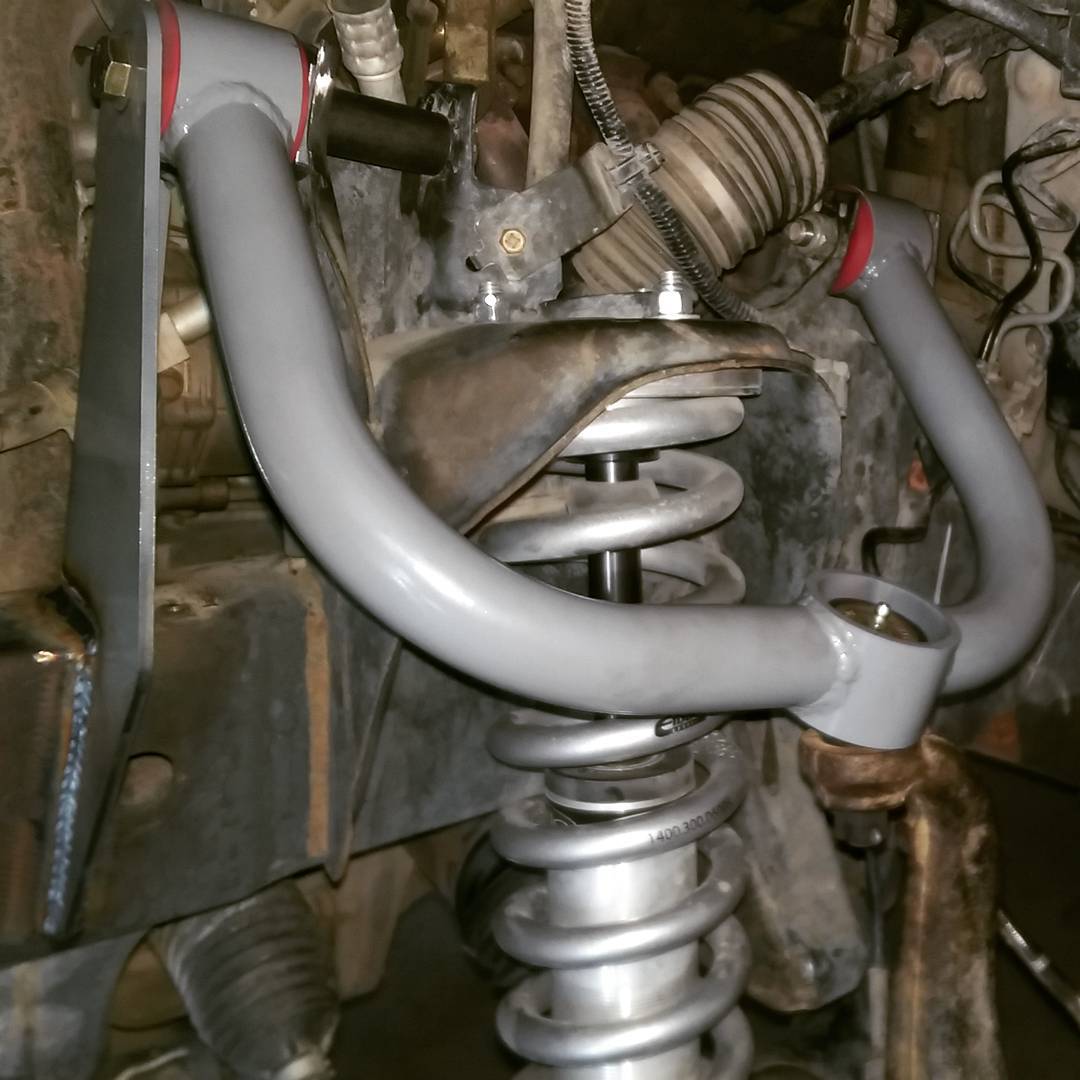

So, whats the solution? A unique, upper control arm design that would have a wider mounting width at the frame. This would completely clear the coilbucket making the common coilbucket contact issues a thing of the past for good. This new design would also use bushings and a greasable balljoint for low maintenance and long lasting performance. The balljoint would be angled in such a way that downtravel is maximized while taking away unused uptravel. This results in about 1.5″ more down travel compared to uniball designs and restores suspension performance at a 4″ lift height. This also allows for a 35″ tire without needing to trim upwrands into the fender and only needing additional clearance near the firewall. At the time Radflo told me that they weren’t able to build IFP (internal reservoir) coilovers for the titan swaps, but with the new added length for this application, IFP became a possibility.

So, whats the solution? A unique, upper control arm design that would have a wider mounting width at the frame. This would completely clear the coilbucket making the common coilbucket contact issues a thing of the past for good. This new design would also use bushings and a greasable balljoint for low maintenance and long lasting performance. The balljoint would be angled in such a way that downtravel is maximized while taking away unused uptravel. This results in about 1.5″ more down travel compared to uniball designs and restores suspension performance at a 4″ lift height. This also allows for a 35″ tire without needing to trim upwrands into the fender and only needing additional clearance near the firewall. At the time Radflo told me that they weren’t able to build IFP (internal reservoir) coilovers for the titan swaps, but with the new added length for this application, IFP became a possibility.

The perfect middle ground.

So, whats the catch? A bracket for the wider mounting width width of the upper control arms needs to be welded in.

We prototyped it, and thats where the titan swap journey stopped.

At the time there were multiple other companies that were really pushing titan swaps, I happened to know the owners of those companies fairly well and simply didn’t want to go head to head with them. As far as second-gen xterras and frontiers go, I was always the gears & lockers guy and they were suspension dudes. Their kits worked well, their reputations were strong and I simply decided to stay in my lane. I also wasn’t sure that the demand would support another titan swap kit in this space. In addition, the jig that we had fiddled with for so long to get this to work just right, was in my Pathfinder when it was stolen and the jig was never seen again.

80,000 miles later and the OG titan swap kits no longer on the market… the question begs. Do I put a compelte kit together? or is the welding too much of a turn off?

Let me know in the comments below

-Steven

Dear Steven,

first: a really honest thank you for the love, time and sweat you still put into the nissan offroad community.

Your blog is always a highlight as it shows the nissan community is still alive and hungry aside from instagram or problem solving in forums.

As far as I can relate, Titan swaps have always been more attractive than SASs due to beeing far less labour and thought-intensive. Shop the parts, unscrew some screws, and its done. Wielding, grinding, and cutting parts on the other hand, always bears the danger of permanently damaging your frame or leaving your pride and joy stranded for some weeks? if something goes wrong. Therefore a lot of people might hesitate. Otherwise, Nissan people seem to get more and more willing to do hardcore mods on their rigs. Take a look at the Pathfinders, neglected for years, now number of rear SASd R51 is continuously rising. Others are installing Armada Subframes in the rear…

Btw. What about a Titanswap rear matching kit for the R51 Platform? Like longer rear arms and CVs for the rear? Maybe that would be a thing to dive into?

Best wishes from Germany! Please keep up the great work!

It looks like a simple add on, a single bracket to weld on with existing brackets used to align it? Brilliant

I’d buy it assuming it’s not thousands of doll hairs for the bracket and arms.

35s are my next step, but I don’t think I want to SAS, ever. Already Titan swapped with locker.

I’m in. i need to get rid of my PRG UCA’s(lack of support).

I run DIRT KING LCA’s and am happy with them so far(years)

ChrisHaynesUSA

That titan swap kit would be amazing and would be interested at looking at costs. For me with my build it’s been the best bang for the buck and making things that people swore wouldn’t work, work with my 2010 Nissan Pathfinder that I just finish SASing the rear end. I feel like the people are scared to go out and piece together there own things for there builds to get them where they want there rigs to be. It’s the lack of complete kits for certain things like for example solid rear axle swap kit, ect. that people just compromised with what they had and didn’t want to explore further.

Short answer: YES, put a kit together. (people that are ok with getting it welded or welding themselves, will do so. And those that won’t, won’t).

Thoughts: With new Frontier out, they are becoming more popular, and attracting more people to the Nissan platforms. Even the existing Frontier/Xterra platforms are becoming more popular, from what I’m seeing, on Facebook and Instagram. People are starting to realize they can get a really strong platform for a lot less than it’s Toyota counterpart. The more companies that can develop good parts for these platforms, the better. Within reason of course, I realize everything has a cost vs return on investment ratio. For instance, one place really lacking for the current Frontier/Xterra is in armor (bumpers front/rear, sliders, skids, aluminum or steel truck canopies, roof racks etc..) compared to other companies that make all of this stuff for other brands. Having a “go-to” titan swap kit that ACTUALLY works properly and is FUNCTIONAL is important. ESPECIALLY when it comes to useable suspension travel. I work for an expedition truck builder and we focus mostly on Toyota, but I’m a Nissan guy myself, and we install a lot of long-travel suspension set-ups on clients trucks. I can’t tell how many times I have to talk people out of going for absolutely maximum height and tire size, for no good reason other than “looks”. I’ve explained MANY times that I’ve personally seen a truck with 2-2.5″ of lift and 33″ tires OUTPERFORM, off road, the same type of truck with 3-4″ of lift and 35″ tires. Most people don’t understand proper up/down travel. Being able to run an extended travel 2.5″ Radlfo/King with remote reservoirs and adjusters, and good, functional upper control arm, and the rest of the Titan parts of course, would be awesome, especially if it can be purchased all from one source. Piecing parts together from a half dozen sources will already turn people off.

There is a hurdle though. A lot (not all) of Nissan owners have these vehicles because of what they got for the PRICE. Some can’t afford the Toyota Tax (myself included), and that Toyota Tax gets place on the aftermarket off road parts as well. Maintaining a balance of cost vs profit will be the hard part. I predict a lot of owners won’t build their rigs, if it costs the same amount as building a Toyota. That’s just my opinion though, based on murmurings from forums and Facebook groups.

Steve. Jay from XN. I think doing welding for a TS is a bit of a turn off. One of the biggest things that I liked about the TS I did on mine was that I could do it in the driveway with wrenches. So making it a welding job might be a turn off. Agree with all your other points though. Personally, I’m pro body lift (2″ max), so my 35s fit perfectly with just a BIT of trimming in the front.

Surpisingly, the feedback I’m getting is more in favor of the kit.

Although your approach does get 35’s in place, it still lacks the adjustment to get a good ride height and a more functional suspension.

Thanks for the feedback!

I have been afraid of the welding aspect turnig people away as well, however, There isn’t any cutting a only minor welding and the ability to go back to the stock arms or other aftermarket arms is retained!

I have been asked about the titan swap or toher R51 upgrades but honeslty… I’m just not seeing the buzz around the Nissans like we did years ago.

If we had more buzz, we woul dhave more products. Sadly, I’m seeing more products getting discontinued than I am seeing new ones brought in.. but I’m still keeping my finger on the pulse of the nissan market with hopes there will be another way and justifiable interest to bring ome of these ideas into reality.

You Nailed it.

I think my biggest trouble these days it trying to get a good read on demand. with the nissan community so fragmented, it’s hard to get a good feel for the pulse and buzzof the niche like I once did.

Without a proper platform to all stay in touch and actually share info like we once did on the forums, I’m completely shooting in the dark with product releases.

The Nissan world has always been small compared to other makes, and at a certain point, it somely doesn’t make any sense to keep creating here.

I really think the communication and community problem needs fixing before too much more goes into products.

Thank you for your feedback.

Exactly, Simple and effective.